ConnecTions wiTh cerTainTy.

E-Mail: info@2e-mechatronic.de Phone: +49 (0)7021 / 93010

plasTic

hybrids

InTelligenT & Flexible

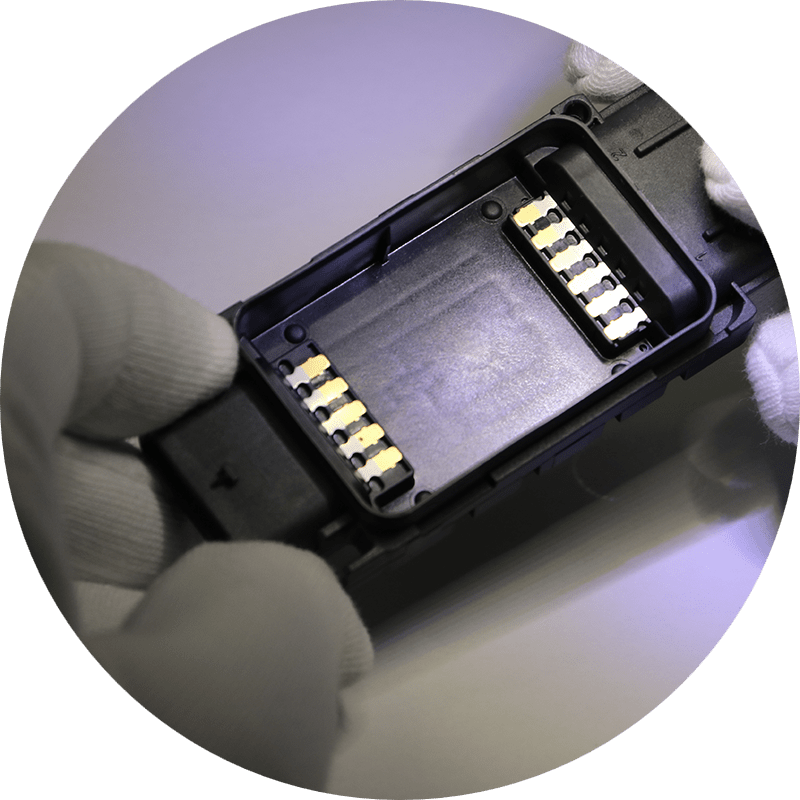

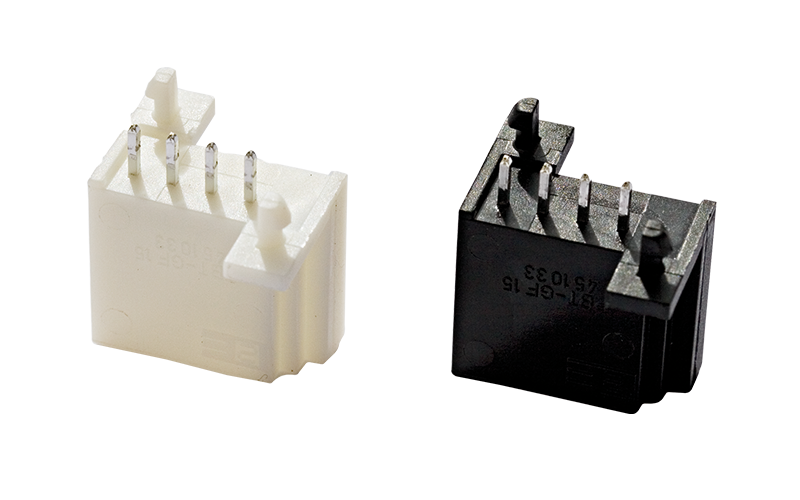

As a competent manufacturing partner for sophisticated plastic hybrids such as sensor housings, contact frames or connectors, we support our customers with know-how and many years of experience. The same applies to product development as well as the optimum design of tools and manufacturing concepts. We specialise in the processing of thermoplastics and inserts using fully or semi-automated processes, also for safety-relevant applications in the automotive industry. 2E mechatronic quality products can be found worldwide in a large number of applications and branches.

FlexibiliTy from developmenT To series producTion

developmenT

2E develops the manufacturing concepts for its plastic hybrids. These are optimally designed in terms of quantity, complexity and customer requirements. A close network of suppliers guarantees the best possible quality and fast delivery times at a competitive price.

QuoTaTion

Before preparing a quotation we carry out a detailed feasibility assessment. Open issues are discussed in a technical meeting and possible solutions suggested. Together with our customers a detailed time schedule is then prepared. Project constraints set by the customer are taken into account in the quotation.

ProjecT planning

After the design has been approved, the tools are manufactured and the systems are set up. Constant coordination with suppliers and customers is particularly important in this context. The complete project management is mapped out by appropriate processes and includes all customer requirements.

ManufacTure

Production is carried out by highly qualified employees, mainly on fully automated machines. Inserted parts such as bushings, contacts with soldering, press-fit and bonding zones are inserted into the injection moulding tool and overmoulded with plastic. Packaging is also fully automated.

TesTing

If required, 100% inspections can be integrated into the production line and performed fully automatically. Only spot checks are performed manually. Visual inspection stations and coordinate measuring machines are available close to the production line for this purpose.

developmenT

2E develops the manufacturing concepts for its plastic hybrids. These are optimally designed in terms of quantity, complexity and customer requirements. A close network of suppliers guarantees the best possible quality and fast delivery times at a competitive price.

QuoTaTion

Before preparing a quotation we carry out a detailed feasibility assessment. Open issues are discussed in a technical meeting and possible solutions suggested. Together with our customers a detailed time schedule is then prepared. Project constraints set by the customer are taken into account in the quotation.

ProjecT planning

After the design has been approved, the tools are manufactured and the systems are set up. Constant coordination with suppliers and customers is particularly important in this context. The complete project management is mapped out by appropriate processes and includes all customer requirements.

ManufacTure

Production is carried out by highly qualified employees, mainly on fully automated machines. Inserted parts such as bushings, contacts with soldering, press-fit and bonding zones are inserted into the injection moulding tool and overmoulded with plastic. Packaging is also fully automated.

TesTing

If required, 100% inspections can be integrated into the production line and performed fully automatically. Only spot checks are performed manually. Visual inspection stations and coordinate measuring machines are available near the production line for this purpose.

developmenT

2E develops the manufacturing concepts for its plastic hybrids. These are optimally designed in terms of quantity, complexity and customer requirements. A close network of suppliers guarantees the best possible quality and fast delivery times at a competitive price.

QuoTaTion

Before preparing a quotation we carry out a detailed feasibility assessment. Open issues are discussed in a technical meeting and possible solutions suggested. Together with our customers a detailed time schedule is then prepared. Project constraints set by the customer are taken into account in the quotation.

ProjecT planning

After the design has been approved, the tools are manufactured and the systems are set up. Constant coordination with suppliers and customers is particularly important in this context. The complete project management is mapped out by appropriate processes and includes all customer requirements.

ManufacTure

Production is carried out by highly qualified employees, mainly on fully automated machines. Inserted parts such as bushings, contacts with soldering, press-fit and bonding zones are inserted into the injection moulding tool and overmoulded with plastic. Packaging is also fully automated.

TesTing

If required, 100% inspections can be integrated into the production line and performed fully automatically. Only spot checks are performed manually. Visual inspection stations and coordinate measuring machines are available close to the production line for this purpose.

QualiTy

Certification in compliance with the automotive

standard IATF 16949 guarantees a standardised

documentation of your products.

The tools we use effi ciently guide us through the project from development via the quality control department to manufacturing and dispatch. A lean interdepartmental project team considers the needs of all involved parties from the outset. Together it develops, for example, the producibility evaluation including risk assessment, FMEA and QM plans. The document exchange service guarantees prompt distribution of updated documents within the company as well as to our customers and suppliers. Customers receive samples according to their requirements, in most cases after the PPAP or VDA process. However, should any complaints arise, a well-established complaints process with analysis tools and 8D-Report is at our disposal.

Successful certification by the TÜV SÜD Management Service GmbH: ISO 14001, ISO 9001 and IATF 16949.

safeTy and susTainabiliTy

Our products are mostly installed in safety-relevant applications such as, for example, housings for sensors which can intervene in the brake system of a vehicle.

This demands a more critical inspection severity, monitored test equipment, extended documentation and better product traceability. With our extensive experience in this area we design our equipment and processes in accordance with the requirements and proactively suggest possibilities for improvement.

At 2E sustainable action is practised in all areas. For us this means pursuing a medium and long term strategy in all decisions and continuously implementing the necessary measures. Our internal procedures and solutions are committed to this concept. 2E thus directly supports active environmental protection. We are proud of our many awards in the fi eld of ecology.

2E processes almost all technical thermoplastics including PPS and LCP.

To the products:

all Housings

Standard connectors

customized connectors